Wedding Ring Workshops in Berlin

For the unique and individual promise you make to each other, self-made wedding rings are the most precious symbol. In a one-day workshop I will guide you in making your own rings. In addition to an intense and emotional memory of this day, you will craft high-quality, unique pieces to take with you on your life’s journey.

Creating rings (and memories) for the future

After a detailed preliminary discussion, during which we will find out together which material, which shape and which proportions suit you best, you will forge your own wedding rings in a special, personal goldsmith course in my small workshop in Zehlendorf. I look forward to supporting you in developing your individual wedding rings with my more than 20 years of experience.

There must be at least one week between the preliminary talk and the workshop. Please contact me for further information or read testimonials from previous clients.

Shamanic initiation ritual

If desired, the workshop can include a shamanic initiation ritual. With my background in energy medicine (a healing system authored by the indigenous Q’ero tribe in Peru) and my many years of spiritual practice, I will be happy to advise you on this very extraordinary blessing.

Example

Lady’s ring

size 56 width 3mm thickness 1,8 mm

weight in 18kt gold ca. 5,5g

weight in 14kt gold ca. 5g

Gent’s ring

size 63 width 4mm thickness 2mm

weight in 18kt gold ca. 8g

weight in 14kt gold ca. 7,5g

Prices

workshop: 150,- € + material

1g 22kt gold (09/2019) 125,- €

1g 18kt white gold (09/2019) 135,- €

1g 18kt gold (09/2019) 105,- €

1g 14kt white gold (09/2019) 120,- €

1g 14kt gold (09/2019) 90,- €

all prices plus VAT

(ca. +15% in 2022)

Explore our ring making workshop in Berlin

Step 1:

The material is prepared to your individual dimensions according to your wishes, which we’ll determine in a preliminary phone call before the workshop. Based on the ring size (the desired width and thickness) this results in a specific weight depending on the material. This weight is then used as a basis for the calculation. On the morning of the workshop, the two rectangular profiles are ready. (Changes to ring design are then no longer possible.) The curvature of the surfaces is shaped with a hammer in the workshop.

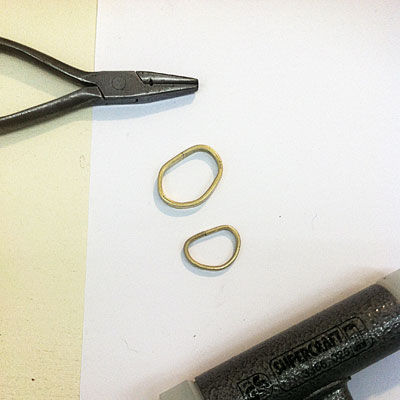

Step 2:

The profiles are pre-bent with special ring bending pliers. It is important that the profile lies parallel in the pliers. It does not have to be round yet; that comes later.

Step 3:

The ends are now tapped parallel to each other in the vice so that the transitions are perfect and the rings can be soldered shut.

Step 4:

Now it’s time to solder, the most exciting moment of the day! The ring is clamped in soldering cross tweezers, the soldering point is brushed with flux and a piece of solder cut to size is applied. We then carefully heat the ring, as the flux vaporizes and the solder tends to bounce off the material. As soon as it sticks well, the complete ring is heated until it glows cherry red. As soon as the solder melts, caution is required, because eventually the material will melt as well. During soldering, I am of course present and announce every move. Afterwards, the rings are pickled to remove the flux residues.

5th step:

Now the rings are rounded on the on the ring stock. Particularly at the beginning, care is required, as the ring still has a large distance to the ring stick and the plumb line can open up again if the ring is hammered too hard. When the ring is in contact with the ring stick, it is compressed into a perfectly round shape in the wedding ring machine.

6th step:

In preparation for modeling the surface curvature, the rings are soft annealed. A small metal hammer is now used to create the curvature always at the same angle and with constant impact force. The hammering structure can be retained as a design element.

7th step:

If the rings are to be smooth and even, they are now finally trimmed, i.e. the hammered texture is filed away and the surface is sanded with increasingly fine sandpaper.

8th step:

If a polish is desired, the rings are first pre-polished with a paste that still contains very fine abrasive particles and finally finely polished so that you can see yourself reflected in it. Finished!

If desired, stones can be added or the rings can be engraved.

Schedule a call

Please contact me if you have any additional questions, need an estimate or would like to schedule your workshop.